Lately there has been a lot of goofing around, mishaps, slacking off, unexplained clutter, costly mistakes, rework and general mayhem in the shop. As result and as you might expect, productivity and output has been low and scrap and waste loss has been high.

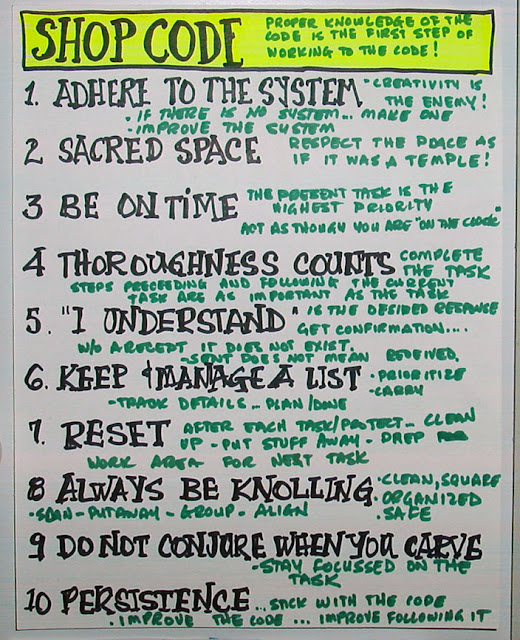

To resolve this I decided that the shop needed a set of rules or CODE as it might be. Having a CODE would help govern behaviour and activities in the shop so the shop could be more productive and more predictable in terms of quality and quantity of output. This would also make the shop a much more pleasant place to work and be.

I did a little research and found a set from a blog called Flying Shavings. I found that I could modify the only slightly to best meet the needs of my shop.

So effective immediately, this CODE and its tenants are in place. Everyone who uses the shop has been duly notified of their existence and violators will be dealt with in the most extreme manner ( yet to be determined).

This is the first round and these will be renewed as required and as better and more profound thought for this CODE comes to mind.

Here they are.

Credit and thanks to Tom Sachs of the Flying Shavings Blog for his work in this important area of running a shop / studio and for 9 of the 10.

Welcome

This is a Journal of my work/craft explorations. It will contain a variety of projects, both in progress and complete, summaries of things I learn from these projects that are worthy of recording and things of interest that I discover along the way. The projects will include woodworking for the home and shop, decoy carving and painting, airbrushing and restoration of equipment and tools.

I am blessed to have the luxury to pursue just about any interest that fancies me at any time. This Blog/Journal is my repository for the pursuit of these fancies. Text will be minimal, the photos plentiful and the posts timely. Enjoy.

Saturday, January 26, 2013

Friday, January 25, 2013

@#$%$#**&@#

Not such a good start today. While holding the bird for some sanding, the primary flight feather broke off. While not catastrophic, it will require considerable time to make an undercut and insert. In the end it will be stronger.

Also, after letting the bird "rest" for a few days, I am not feeling so good about the head fit and the angle of the head. It feels like it is aiming too far down

This post will be dedicated to getting the head right before continuing on. The sooner I get this right/ close to right, the better it will be for carving refining the rest of the bird.

|

| Broken primary feathers. |

|

| Trial fit of the head...still not right...she is looking too far down. |

|

| The angle of the bill is still too low for the attitude I am trying to achieve and the gap between body and head begs refinement. |

|

| Some refinement of the joint....but still not enough of a change of the angle. |

|

| Right angle AND attitude...at last. |

|

| Different views...the butt is a bit too fat "butt" I will get that later |

Fine Tuning the Fine Feathers

With the head fitted onto the body, it is time to refine the body of the duck. First, however, I noticed that when I was adding this post, I discovered that text was missing from the 12/26/12 Post named Cut & Rough Out the Body. As a result I edited this so if anyone cares to, they can go back and read the additions to the last 1/2 of the photos.

|

| Int he 12/26/12 post, I discuss the fact that the butt of a duck is nearly perfectly round and when viewed from the rear can be seen as a series of concentric circles. |

|

| Here is the development of the other side of the bird. Here the wing is tucked into the side pocket and the feathers that are exposed are only the tertial and primary feathers of the wing. |

|

| Nice close up view of the exposed wing. There are two or three spots where the feathers will be separated to give this a very realistic feel. |

Sunday, January 6, 2013

Trial Fit the Head & Refine The Fit

This is where the bird begins to come to life albeit slowly.

|

| Second step is to place the head where it will eventually go and rub the two surfaceses together. |

|

| The high posts are covering in carbon. these are these spots to grind down |

|

| After about 10 times of doing this, the surfaces mate nearly perfectly. |

|

| Trail fit #2..... |

|

| Different view. |

|

| Another view. |

Subscribe to:

Comments (Atom)